?What is Cylinder Liner/Material cylinder liner

:CYLINDER LINERS

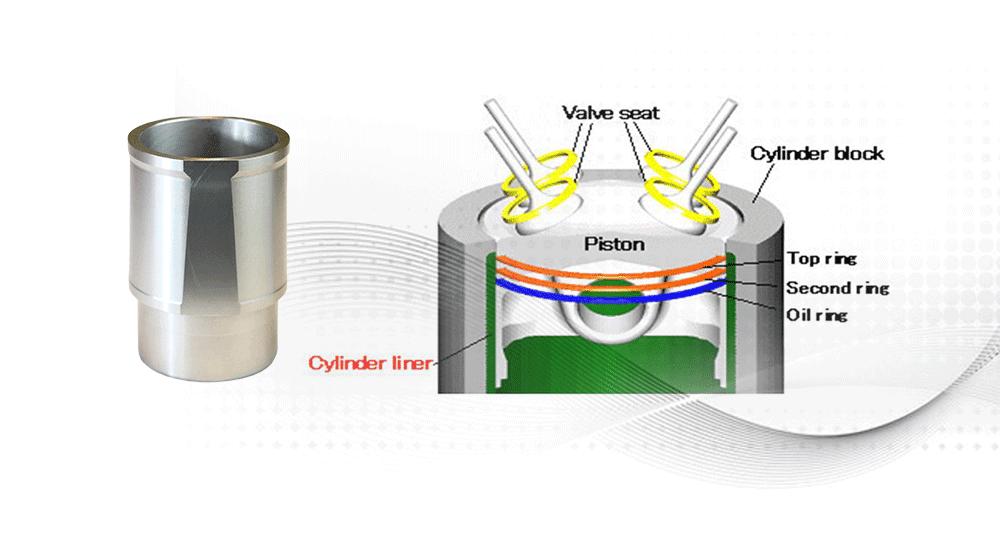

Cylinder liner is a hollow cylindrical shell which acts as the enclosre in which the combustion takes place

A cylinder liners is a removable component, cylindriacal the surface for the piston to slide and carry out its compression task. It can be replaced when worn out

Cylinder liners are made from close grained cast iron

:Conditions to meet

Strength –

Wear resistance –

Corrosion resistance –

:Material cylinder liner

Gray cast steel +vanadium & titanium –

Chromium plate liner (to reduce wear) –

Close grained cast iron or –

Fine lamellar cast iron (in recent designs) –

:Wet Liners

In wet liners the water is in direct contact with outer surface of the liner

:Dry Liners

In dry liners the water is in indirect contact with outer surface of the liner, i.e. cylinder casting contains wet jackets

Should be included in the original cylinder liner design –

A leak proof joint between cylinder casting –

and liner should be provided

Less robust –

Can be finished before fitting –

Provided either in the original design afterwards –

There is no requirement for a leak proof joint –

between cylinder casting & liner

A cylinder block with dry liners is more –

robust than with wet liners

Cannot be finished before fitting to cylinder block –

:PRODUCTION OF LINERS

Construction is done either by centrifugal casting in case of –

smaller liners and sand casting in case of larger liners

The inner surface of the cylinder liner is usually chrome plated to –

make it smooth

But this smoothness does not allow oil to spread –

out properly thus affecting liner lubrication

in a negative manner. This was rectified

to a certain degree through the use of

porous chrome honing

In order to provide a harder –

wearing surface, the bore of liners is

subjected to the process of liners

is subjected to the process of nit riding